Nordic Ware Baking tray Stadion, 9 cup blue, 59124

Nordic Ware Baking tray Stadion, 9 cup blue, 59124

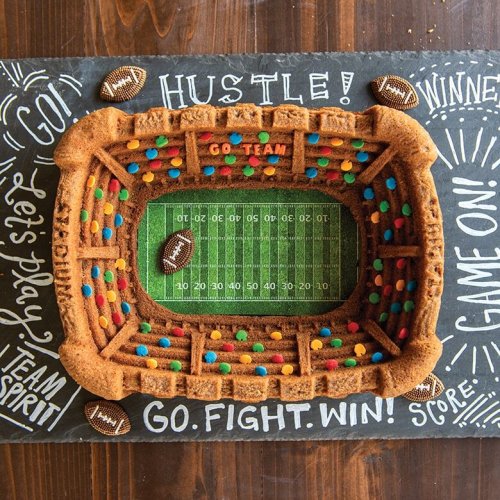

A detailed cake in the shape of a football stadium thanks to the new Nordic Ware baking mould will be just the right surprise for all young and old footballers. Volume 9 cup (2.13 l), grey-blue colour. More

Product code: 59124

Shipping and Payment

€ 56,25 incl. VAT

A detailed cake in the shape of a football stadium thanks to the new Nordic Ware baking mould will be just the right surprise for all young and old footballers. Volume 9 cup (2.13 l), grey-blue colour. More

Product code: 59124

Shipping and Payment

Nordic Ware Baking tray Stadion, 9 cup blue

It will be up to you whether you make a stadium for American football or our European football with this imaginative decoration. What's more, the shape of the mould can also serve as an imaginative tray for savoury or sweet treats at home parties.

- Material: cast aluminium, non-stick surface

- Can be placed in an oven with a maximum temperature of 200°C.

- Colour: grey-blue

- Capacity: 2.13 l (9 cup)

- Dimensions: 30,8 x 24,6 x 7,6 cm

- Weight: 1.13 kg

- Health-safe

- Made in the USA

The mold is made of solid cast aluminum to ensure perfect heat distribution. The manufacturer himself recommends that the baking temperature be lowered by up to 15°C than indicated in the recipes. For the best possible result , we recommend baking doughs that are denser (buttery, rubbed, yeasted), which will make all the details of the mould stand out.The mould can be placed in an oven with a maximum temperature of 200°C inclusive.

Maintenance instructions:

Wash by hand with warm soapy water before first use and after each subsequent use.

Do not use metal objects or wires.

Use a soft brush to remove stubborn dough deposits.

Fill the mould to a maximum of 2/3 full.

Never use olive oil, sunflower oil or other common table oils for greasing.

We recommend greasing the mould with lard or clarified butter, or spraying it with special spray oil and dusting it with semi-coarse flour.

Human approach

Nordic Ware's beautiful cake moulds are made with visible human care, and not only because they are also hand-finished. They have been perfecting the process of creating unique bundt cakes for over 70 years, so that the moulds are not only unique but also functional. Each product has been through two dozen sets of hands before it leaves production to ensure the highest quality.

Material

The aluminium used to make the moulds is first melted at 650°C and thenNext, the liquid aluminium flows into a holding chamber where a pressure arm pushes the liquid aluminium into the mould. This process must be fast, taking only a few seconds to solidify the aluminium. The mould is then opened and the very hot but solid aluminium mould can be removed. Aluminium is easy to shape, so Nordic Ware moulds can be shaped to the smallest detail.

Surface

The mould still has a long way to go and the first step is to trim the excess aluminium around the perimeter of the mould. It is then sent for further processing, where it goes through a series of finishing processes, including starting vibratory equipment, corrosion protection spraying and surface roughening. Next, they are thoroughly washed and transferred to the production process by non-stick surface spraying and curing with a PFOA-free resin .

The American brand Nordic Ware began its history in 1946 when David Dalquist, a metallurgical engineer with Swedish roots, founded the company with his wife Dorothy. It didn't come to the attention of customers until 1950, when a group of housewives visited David and asked him to create the classic cake mold they knew from their European homelands. David granted their request and created the world famous Bundt, the patented name for the bundt cake mould. The next twist came in 1966. A prestigious baking competition (the Pillsbury Bake-Off) was held in Houston, USA, where contestant Ella Helfrich placed 2nd. With a Nordic Ware mould with a hole in the middle, she baked the now iconic Fudge Tunnel recipe, which guaranteed fame not only for her but also for the Nordic Ware brand, which became an overnight hit.

Today, nearly 70 million households have a Nordic Ware mold , and that number is still growing. The company is headquartered in Minneapolis, Minnesota, where it also has a development centre. In fact, the Nordic Ware brand is constantly renewing its product range with new shapes and seasonal moulds. When a mould is designed, a 3D model is first printed and then the mould production can begin. Everything from the creation to the shipping of the product is done in one place.